Welding bar

Features

- High-quality Busch vacuum pump

- Deep-drawn vacuumchamber

- High pressure seal welding

- Cable-free welding-bar construction

- Starter kit with consumables (teflon tape, welding wire) included

suitable for:

Feature Equipment MAX-F 46

Seal welding

Accessories

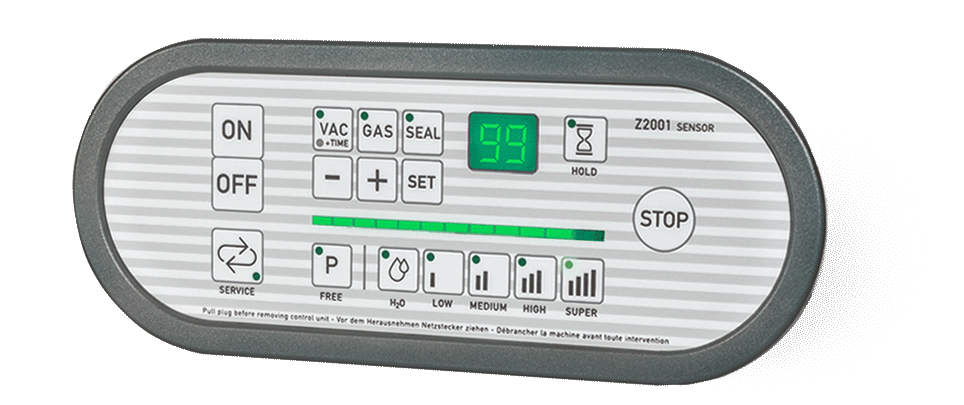

- Programmable sensor control system Z 3000 incl

- High pressure seal weld

- Gassing unit with 3 nozzles (we recommend the sensor control system Z 3000)

- Slanted bag holder for packaging of liquids (stainless steel)

- Suction device for standardized catering boxes

- Soft ventilation (only available in combination with sensor control system Z 3000)

- Extra charge for AC version of pump 25 m³/h, 1 phase, 230 V, 50 Hz

- Higher performance vacuum pump with 63 m³/h, 3 phases, 230/400 V, 50 Hz, DC

- Specially shaped plate to fill the hollow space of the chamber Stainless steel lid (usable height 230 mm)

- Over-/ under seal weld (only available in combination with stainless steel lid)

- Lid inspection window (only available in combination with stainless steel lid)

![[Translate to Englisch:] Steuerung Z 3000](/fileadmin/user_upload/produkte/steuerung/z3000.png)