BASIC-F 700

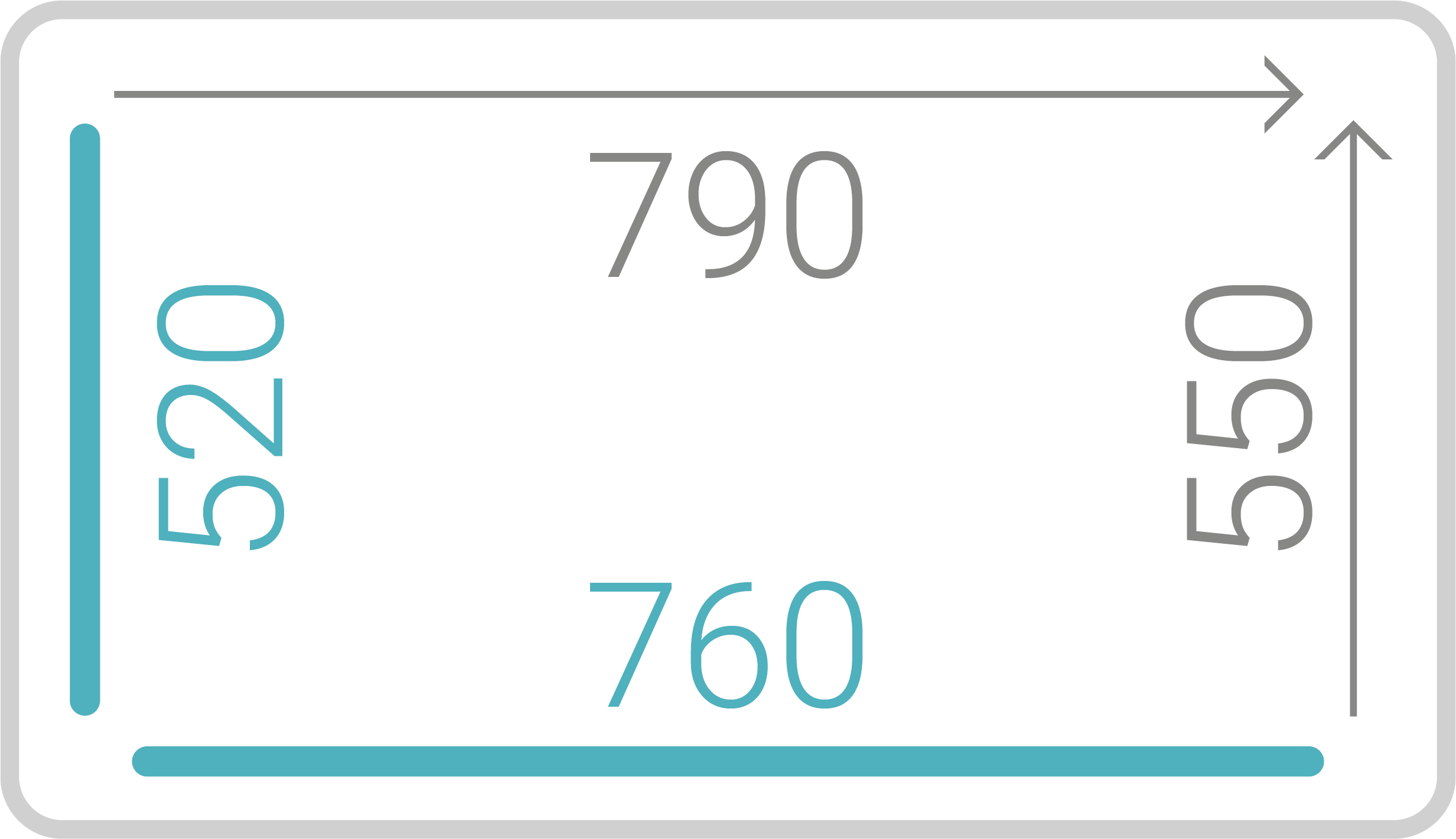

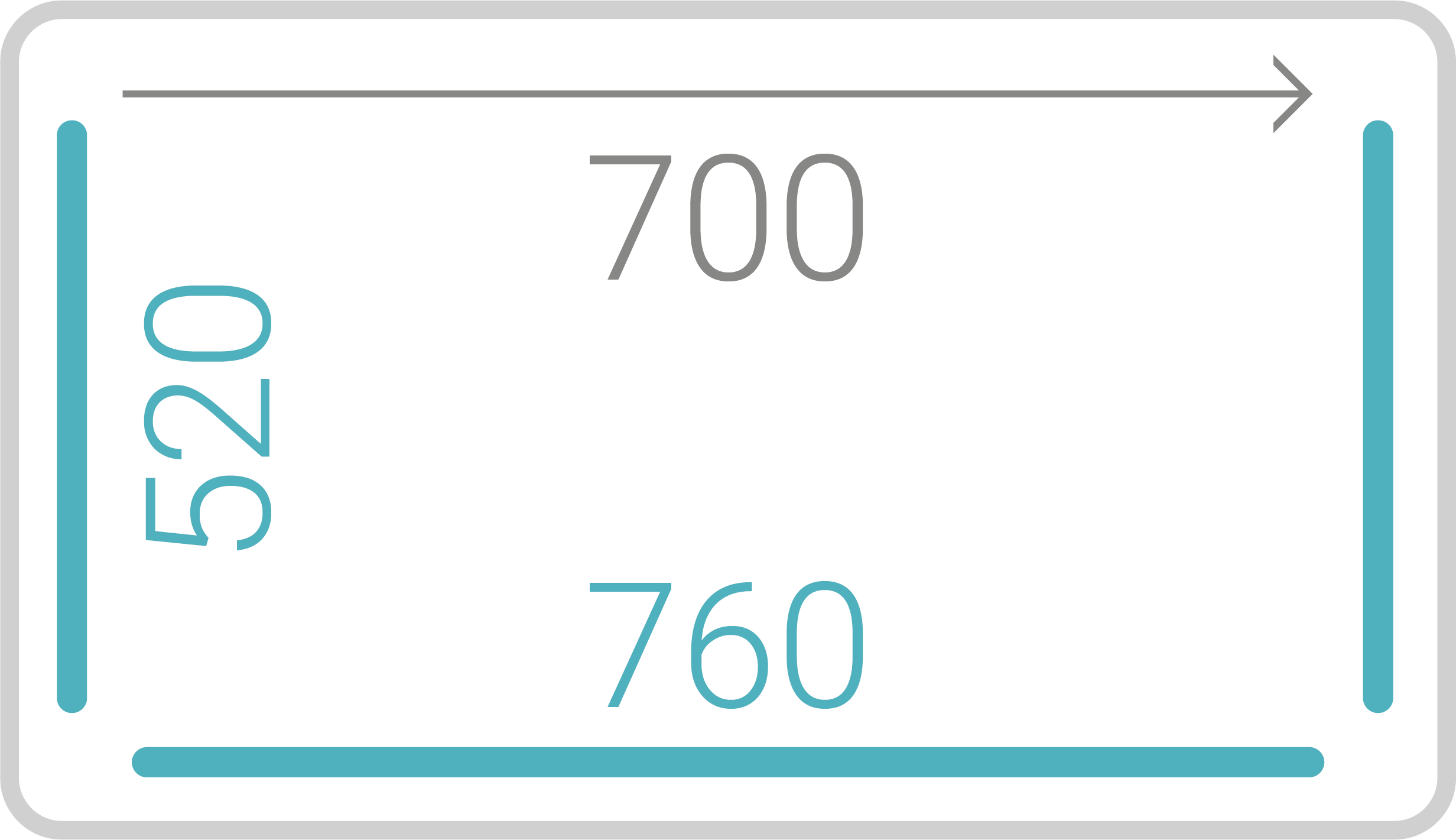

Internal chamber dimensions:

850 x 615 x 225 mm*

External dimensions:

970 x 870 x 1070 mm*

Seal length:

520 mm | 760 mm

Vacuum pump:

63 m³/h | 100 m³/h

Weight:

216 kg | 234 kg

Power supply:

3 Phasen, 230 / 400 V, 50 Hz**

(Special voltages on request)

* Width x depth x height

** Special voltage on request

All dimensions are approximate,

technical changes reserved

Welding bar

Features

- High quality vacuum pump

- Sealing by pressure hoses in the lid. Can be supported with compressed air.

- High quality and stable lid

- 4 robust stainless steel rollers, 2 of them lockable

- Initial equipment Consumables (Teflon tape, wire) included

suitable for:

Equipment BASIC-F 700

Seal welding

Accessories

- Pump 100 m³/h (Busch)

- Simple separation welding

- Separately adjustable separation welding or top / bottom welding

- Volume reduction in the lid

- Gas flushing, 4x3 nozzles

- Soft ventilation

- Set of wearing parts (Teflon, wire, lid gasket, silicone for pressure bar)

- Installation and instruction on site