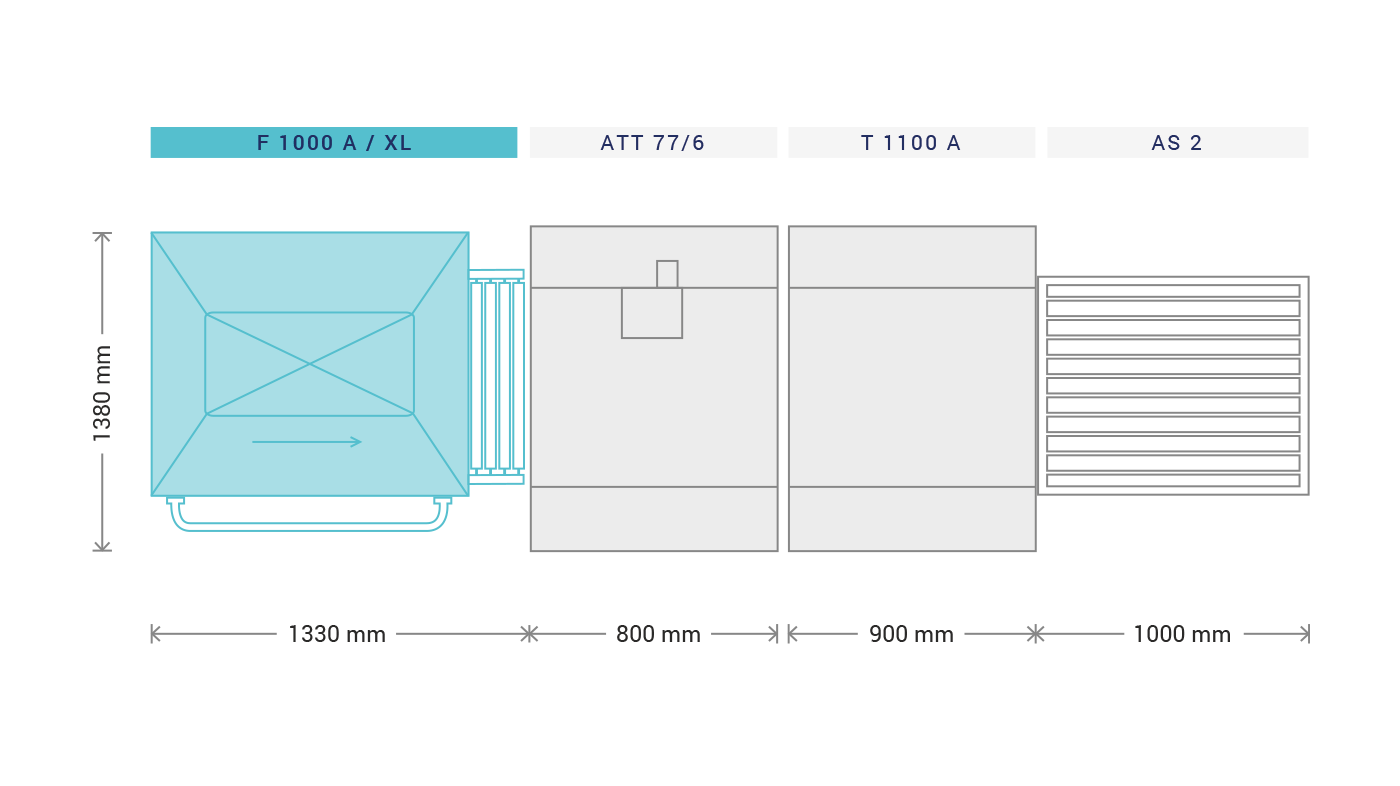

Titan-F 1000 A/XL Conveyor belt machine

Internal chamber dimensions:

1015 x 805 x 210 / 280 mm

External dimensions:

1330 x 1170 x 1100 mm

Seal length:

600 / 680 / 980 mm

Vacuum pump:

160, 250 oder 300 m³/ h

Weight:

ca. 380 / 450 kg

Power supply:

3 Phasen, 230/400 V, 50 Hz

(Special voltages on request)

Welding bar

Features

- High-quality Busch vacuum pump

- Platform-style construction for easy cleaning

- High pressure seal welding

- Robust stainless steel lid – with inspection window upon request

- Automatic product removal using height adjustable conveyor belt

suitable for:

Feature Equipment TITAN-F 1000 A/XL

Seal welding

Accessories

- Gassing unit with long stainless steel nozzles (5 nozzles per bar )

- Simple cut-off seal weld

- Separately adjustable cut-off weld

- Over-/ under seal weld (not possible in combination with separately adjustable cut-off weld)

- Soft ventilation

- Lid inspection window

- Higher performance vacuum pump with 250 m³/h, 3 phases, 230/400 V, 50 Hz, D.C.

- Higher performance vacuum pump with 300 m³/h, 3 phases, 230/400 V, 50 Hz, D.C.

- Lid automation

- Movable bridging rolling track at the right side of the machine

- External control unit positioned a lateral or a rear stainless steel arm

- Lid-volume reduction (3 specially shaped insertion plates with stainless steel fastenings)

![[Translate to Englisch:] Steuerung Z 3000](/fileadmin/user_upload/produkte/steuerung/z3000.png)